What is dry-on-dry?

With our product EF26, we offer an innovative solution to

cure both the primer and topcoat together at a lower temperature.

We call this technique “dry-on-dry” and is especially created to optimize the curing and production process. When they are cured separately, many factors can influence and lessen the adhesion between the two. This risk is completely removed thanks to our technique.

How does it work?

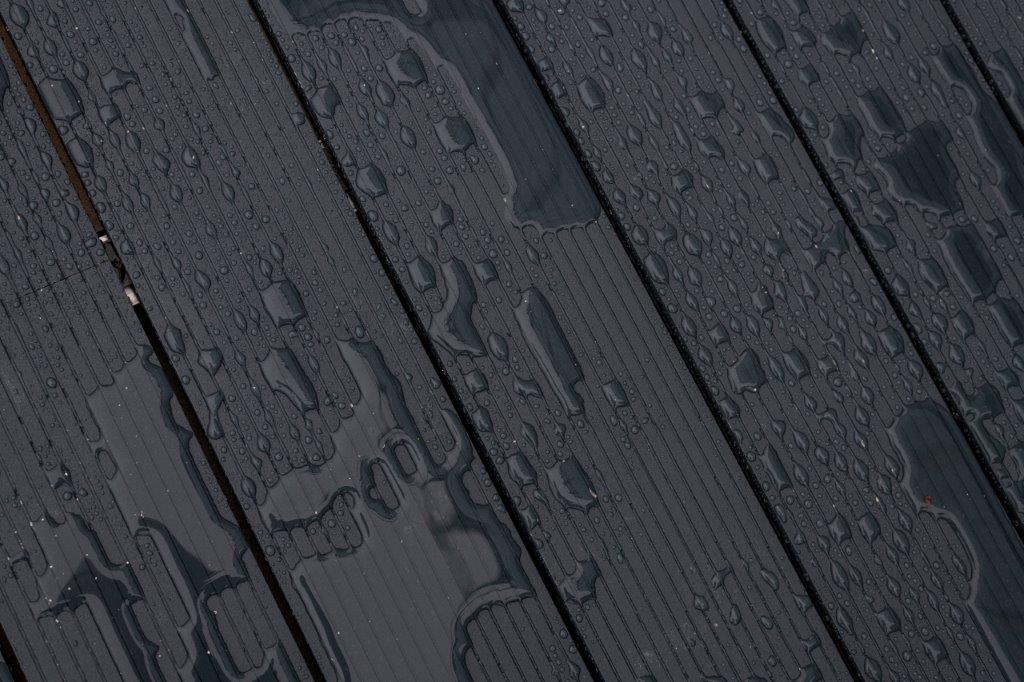

EF26 is a powerful, reactive primer that provides an excellent edge coverage with a thin layer of powder coating. In combination with our topcoat PE40-FE, excellent results are obtained. It ensures that your products will withstand all weather conditions and their quality will be optimes.

PE40-FE is a high-quality powder with very good outdoor resistance and is approved by Qualicoat as well as Qualisteelcoat. This powder is – amongst other qualities – known for its excellent degassing characteristic.: your coatings will be as good as free from craters, air bubbles or pinholes. Furthermore, PE40-FE is suited for curing at temperatures starting 150°C.

With EF26 + PE40-FE your products only need to be cured once.

Dry-on-Dry technology Reduces production time and costs while lowering energy usage and CO2 emissions

In short, with our EF26 and PE40-FE we offer a unique combination of technologies and products that lift your production process and end result to a higher level.

Industry Applications

The Protech Group’s Dry-on-Dry Technology offers unparalleled performance in a variety of applications.

- Compressors

- Army bed bases

- Earth-moving machinery

- Agricultural machinery

Case Studies

Corrosion and blistering are common problems during the lifetime of coatings on metal.

A primer is often applied to the metal substrate for enhanced protection.

That’s why we’re excited to introduce our Dry-on-Dry technology, a solution that revolutionizes the coating process.

But how effective is Dry-on-Dry really?

Our R&D department conducted 3 neutral salt spray tests according to ASTM B117-07 on bare steel that was pretreated with iron phosphate and then passivated.

- Primer EF26 and topcoat PE40-FE with a total layer thickness of 70 – 90 µm.

- Primer EF26 and topcoat PE40-FE with a total layer thickness of 90 – 110 µm.

- Only topcoat PE40-FE with layer thickness of 80 µm

Here are the results:

1. Corrosion

| Corrosion | EF26 + PE40-FE (70 – 90 µm) | EF26 + PE40-FE (90 – 110 µm) | PE40-FE (80 µm) |

| After 750 hrs | Yes (S) | Yes (S) | Yes (S + E) |

| After 1250 hrs | Yes (S + E) | Yes (S) | Yes (S + E) |

| After 2000 hrs | Yes (S + E) | Yes (S) | Yes (S + E) |

If only the topcoat is applied, there is visible corrosion formation on the edges after 750 hours. With a thin layer thickness, this can only occur after 1250 hours; but with sufficient layer thickness of primer and topcoat, we easily reach 2000 hours without any corrosion formation.

2. Blistering:

| Blistering | EF26 + PE40-FE (70 – 90 µm) | EF26 + PE40-FE (90 – 110 µm) | PE40-FE (80 µm) |

| After 750 hrs | No | No | 3 S (2) (E) |

| After 1250 hrs | 2 S (2) (E) | No | 3 S (5) (E) |

| After 2000 hrs | 2 S (2) (E) | No | * |

Only a topcoat, already causes blistering after 750 hours. With a thin layer thickness, blisters will only form after 1500 hours; while with a higher thickness, no form of corrosion is visible even after 2000 hours. Blistering can therefore be prevented with the help of a good primer.

3. Adhesion

The adhesion, or bonding, of the coating to the substrate is important.

It’s not just about protection – it’s about extending the lifespan of your product.

Our research shows that the use of a primer has a very positive effect here. The adhesion of the coating is up to 100% better when a primer is used than when only a topcoat is applied.

In other words, Dry-on-Dry technology can contribute significantly to preventing problems and improving the adhesion of the coating to the substrate. This research shows that the overall coating thickness also plays an important role in protecting the substrate from corrosion and blistering. Moreover, the use of a primer has a beneficial effect on edge protection, especially for sharp edges.

Drive savings and sustainability with

Protech Group’s Dry-on-Dry technology.

Contact us Toll Free: 1 (800) 361-9364

Is Dry-on-Dry technology not suited to your exact needs?

Ask our experts about EF-SERIESTM our line of low bake primers

engineered for a wide variety of applications.

The Protech Group formulates powder coating solutions tailored to our customers’ exact needs. Backed by over 45 years of expertise and the latest in laboratory technology – our chemists excel in formulating the right mix for your application.