How to successfully install

a powder coating line

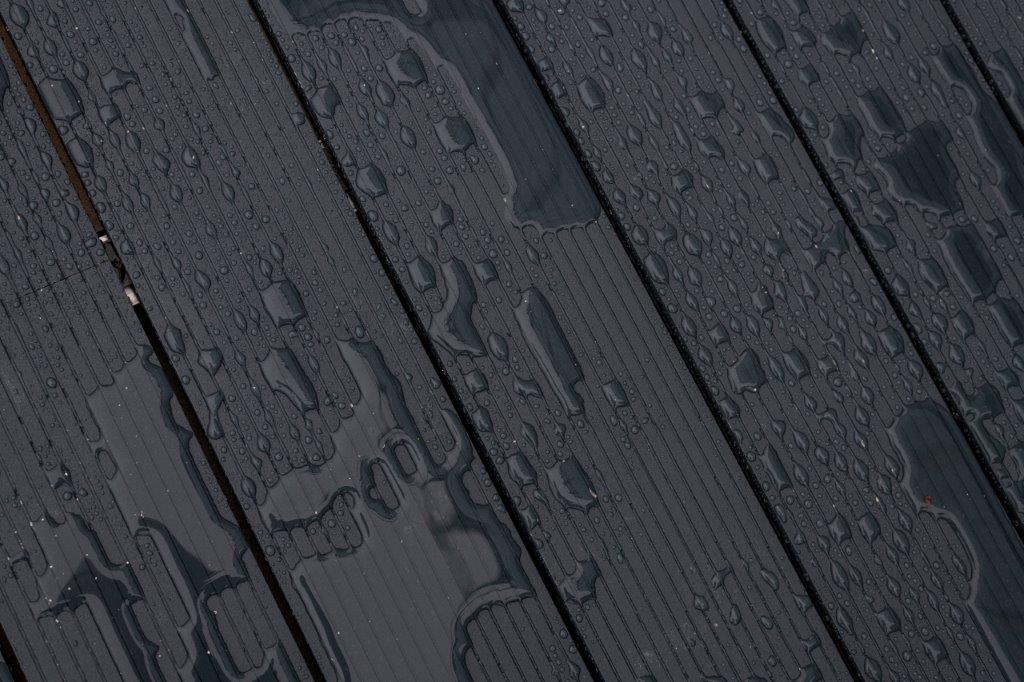

Powder coating provides an exceptional range of finishes to suit most applications, offering flexibility through material choice, and is adaptable for almost any environment. It is also a cost-effective coating solution, both in terms of materials and the automated processes to apply it.

While the application can be fully automated, it does require several processes, and with them, the installation of specialized equipment to carry them out. The way a powder coating line is set up is extremely important, as attention to detail here means a great finish on your products, but cutting corners during setup can mean poor results when manufacturing begins.

What is a powder coating line?

A powder coating line is made up of three different processes:

- Pretreatment Where the product or substrate is cleaned before coating to ensure adhesion

- Application Where the powder is sprayed on, or the product dipped into the powder

- Curing The curing process first melts the powder so that it flows into an even coat, then cures it to form the durable finish

Each application process has its own set of equipment requirements, which will depend on whether you choose to use manual or automated systems. Equipment requirements can also vary depending on the type of application, where spray or dip impacts not just the way the powder is applied, but the speed at which can happen, and the space required to perform this process.

Pretreatment

Pretreatment is an essential part of the process, cleaning and preparing the object’s surface so that the powder will adhere to it properly to provide the long-lasting coating you are looking for. That means removing dust and debris, oil leftover from machining or other processes, and the removal of rust or other finishing materials.

The kind of pretreatment needed will depend on the types of products being coated. Some may require blasting to clean up, others may just need a wash.

A blast room provides a self-contained environment that enables an appropriate blast media, which could be sand, grit, or steel shot, to be fired at high speed at the material to be coated until all debris is removed. It uses a high-pressure air system to achieve this, and due to the nature of the process, must be environmentally isolated from other areas of the coating process.

After blasting, and for those products that just require a wash, a wash station is an essential part of the powder coating line. Here parts are sprayed with chemicals or detergent to degrease them and remove all contaminants, so they are clean and ready for coating. Some applications may need a dry-off oven after this to remove all traces of moisture. Heating here can also aid the coating process, although some powder coating lines do without this drying process, depending on how quickly a product needs to move between the wash and application stages.

Application

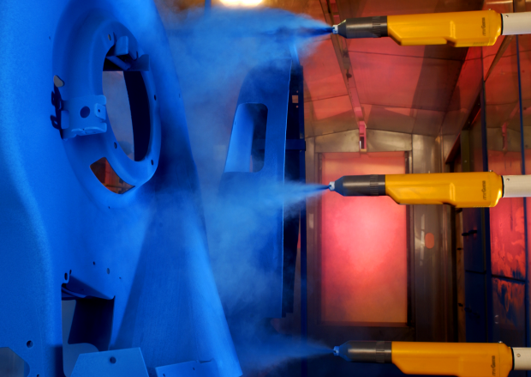

There are two options here, spray or dip. Spraying is by far the most common, but both applications rely on the same technical process. The powder is given an electrical charge, whether by the bath in the case of dipping or by a special spray gun in the case of spraying. This causes the powder particles to be attracted to the product being coated, so they stick to the grounded product.

A powder spray booth is an area that is kept environmentally separate from the rest of the building, preventing overspray from contaminating every surface it touches. Isolating the spray booth also makes collecting overspray for reuse much easier, reducing waste to virtually nothing.

There are various types of spray booths available, featuring both manual and automated systems. A fully automated system can be advantageous when it comes to efficiency.

Curing

The most technically complex part of the process is curing. Here, temperature, rate of temperature change, and timings can make all the difference, changing the character of the coating significantly. Get this part wrong, and it can ruin the quality of your coating.

Curing ovens offer precise temperature controls that allow for curing schedules to be developed that deliver the perfect balance of speed and effectiveness to consistently deliver a final coating that meets all expectations for protection.

Building a

Powder Coating Line

Building a line means selecting the right equipment that meets your needs. If you have a small run of products that are done by hand, then obviously the equipment required will be much reduced compared to someone setting up a fully automated production line to coat hundreds of products per day.

Understanding your own needs is a big part of planning the installation. Think about how you will coat products. If it’s a manual system, will it be faster to work in batches? If so, you will need a spray booth big enough to fit them. Think about how best to optimize your process, and if working on 20 products at a time is the best outcome, you need a paint booth and curing oven big enough to fit those 20 objects in.

As you can see, the key to setting up an effective and efficient powder coating line is to assess your own specific needs and plan accordingly. In addition, think about how the product will move through the various stages of the process, from pretreatment to application and curing. For automated systems this may be a continual conveyor, for manual systems, ensuring that there is ample room to maneuver parts by hand, and space to store them before being worked on should be considered too.

Through careful planning, and with the help of industry experts, a powder coating line that meets your precise needs can be installed and operational relatively quickly, providing years of effective performance.