Pre-treating a Substrate

for Powder Coating

One of the most critical steps in powder coating is the cleaning and pre-treatment of the substrate. Pre-treatment allows for the proper adhesion of the powder to the substrate, ensuring the maximum coating performance and long-term resistance to corrosion.

Firstly, is it extremely important to know and understand your substrate as different substrates may require particular pre-treatment processes. For example, cast iron and steel may require special rust and corrosion protection, aluminum materials may need to be stripped of their oxide layer so that the powder coating is applied to the bare metal, galvanized metal may need a duplex coating, and hot-dip galvanized metal may require an additional heat-drying step to remove air and moisture from the substrate surface.

Also, it is important to consider the final purpose of the substrate. A substrate intended for a highly corrosive marine environment may require additional rust and corrosion resistance or outdoor applications may need protection from UV rays and weather damage

Bearing in mind these special situations, you can now proceed with the six main steps necessary for the effective preparation of a substrate for thermoset powder coating.

1. Cleaning

It is vital to remove all traces of dirt, dust, grime, grease, and paint from the substrate to ensure that the powder coating will adhere properly. If the surface is not properly cleaned, any remaining residue and deposits could affect the adhesion of the powder and the quality of the final finish. Different cleaning processes can be used, depending on the material and its condition:

- Washing and degreasing with clean, reverse osmosis, or deionized water. A pressure washer can be used to remove tougher dirt. Hot water and steam can also be used when available.

- Weak alkali and neutral detergents in dip tanks can remove oil, grease, and solvents.

- Abrasive blasting involves shooting tiny solid particles at high velocity against the substrate and is used to remove deeper layers of dirt. Typical media commonly used include steel grit, glass beads, bicarbonate of soda, and sand.

- Chemical cleaning can remove organic materials such as oils, coolants, and lubricants. Harsh chemicals, however, can weaken the substrate so should only be used when absolutely necessary.

2. Rinsing

This stage is essential to remove the remnants of any media or chemicals used in the preceding process. It can be done with normal tap water unless you are in an area where the water contains a lot of chlorides or sulfates, which can initiate corrosion. If this is the case, it’s better to use reverse osmosis filtered water or deionized water. Any runoff from the rinsing process needs to be disposed of carefully.

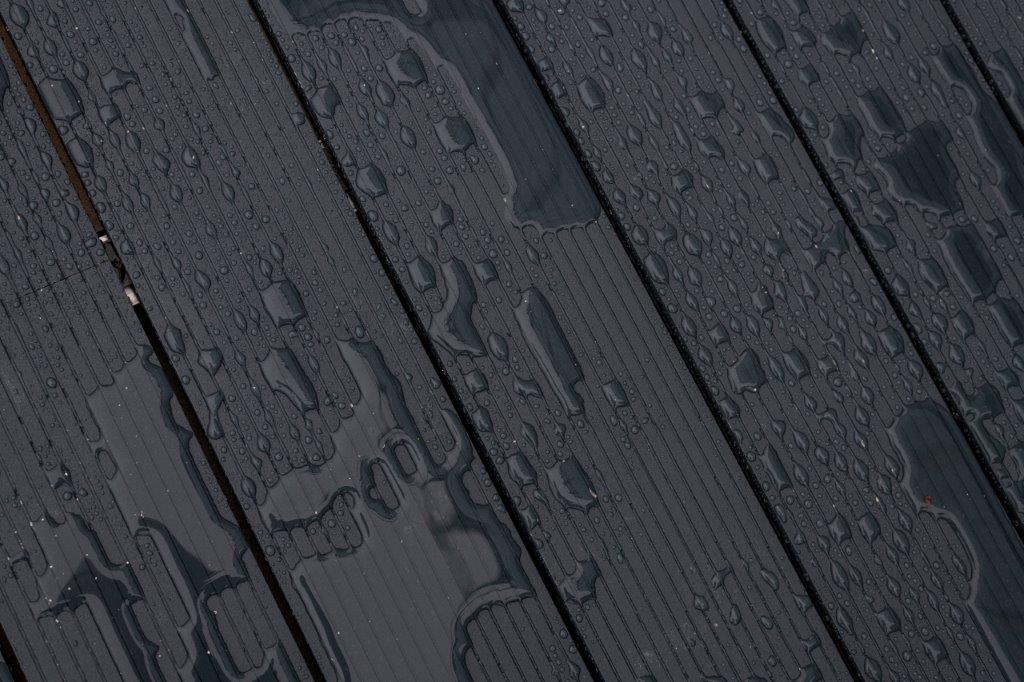

3. Drying

The substrate can be air dried or in an oven. Most ferrous materials are susceptible to rapid atmospheric corrosion or flash rusting, so once the substrate is dry, it is best to powder coat it as soon as possible.

4. Sealing

Phosphate pre-treatment, or phosphatizing, is a process that deposits a layer of phosphate onto the substrate. The phosphate increases corrosion resistance as it forms an inert surface that protects the metal underneath. It also adds texture to the surface of the substrate by creating microscopic pits to which the powder paint adheres. You can choose between iron phosphate, zinc phosphate, or even zirconium phosphate. Iron phosphate tends to be the cheapest solution.

5. Re-rinsing and drying

After phosphatizing, another rinsing stage is necessary, again followed by drying.

6. Masking

It is possible that the entire substrate does not need to be coated. If this is the case, then masking products must be applied to those areas. These are readily available in various shapes and sizes. In general, they are made from plastic film or paper coated with a pressure-sensitive adhesive. They protect the covered areas from coming into contact with the powder coating during the painting process.

These six preparation steps create a surface that allows the powder coating to adhere effectively. In addition, this preparation will increase the performance of the coating, extending its lifetime and helping to prevent corrosion of the substrate.

After following all these steps, your substrate is fully prepared and ready to be powder coated. We will cover the actual powder coating process in a future blog post.

If you have any questions concerning the preparation of your substrate prior to thermoset powder coating, drop us a line and our experts will be delighted to discuss your specific requirements.